The function of the bracket is to protect the photovoltaic modules to withstand 30 years of damage such as sunlight, corrosion, and strong winds. Professional product design makes the solar photovoltaic support system can be assembled with only a few accessories, no other drilling or welding is required, and it can also be assembled quickly on the construction site, which effectively improves the installation efficiency, but also shorten the construction period.

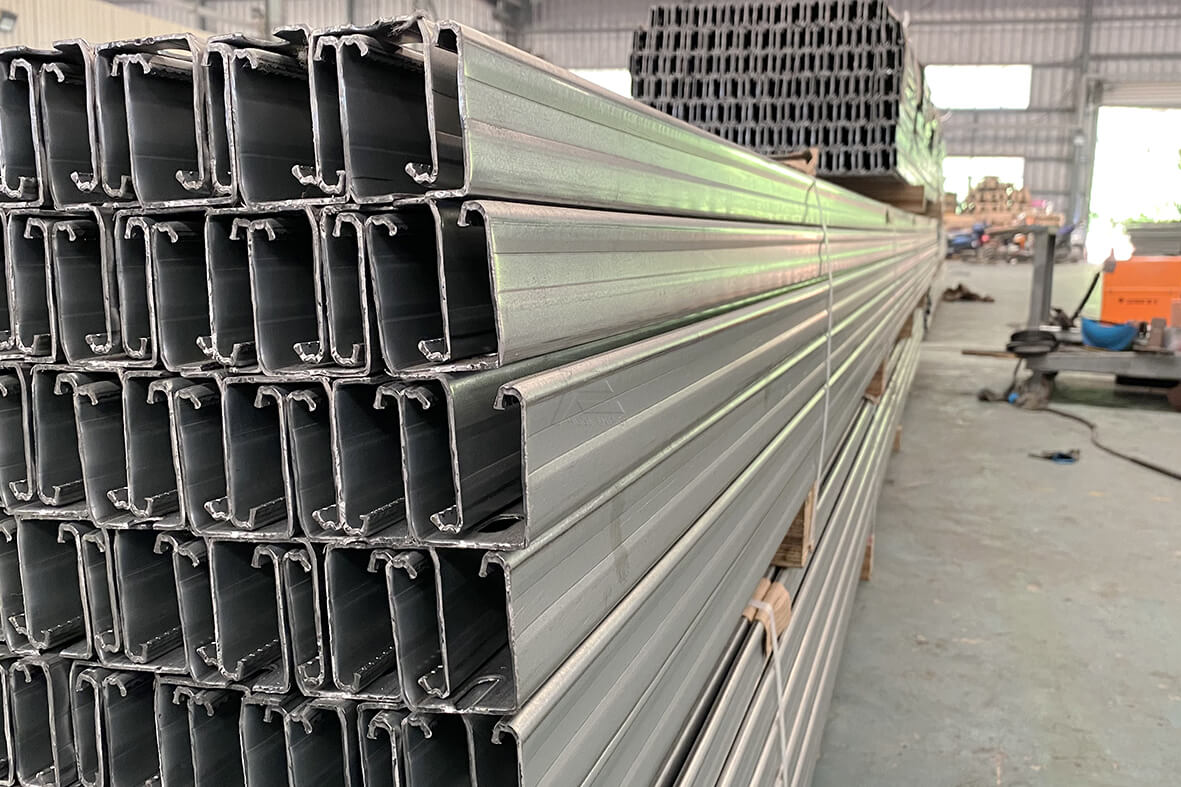

The roof support adopts hot-dip galvanized carbon steel support, and the components are installed on the aluminum alloy purlins by means of backboard or pressing blocks. Fasteners are made of stainless steel. The bracket is designed with a wind resistance of 30 m/s to ensure long-term outdoor use.

Distributed photovoltaic power station for photovoltaic support equipment and technical requirements

1. Material and performance requirements:

(1). Material requirements: The main material of the selected steel structure is Q235B, and the welding rod is E43 series welding rod.

(2). Requirements for mechanical properties: The tensile strength, elongation, yield point, cold bending test and other mechanical properties of the selected steel structure main materials must meet the relevant requirements of "Carbon Structural Steel" (GB/T700-2007) Regulation.

(3). Requirements for chemical composition: The content of chemical elements such as carbon, sulfur, and phosphorus in the selected steel structure main materials must comply with the relevant regulations of "Carbon Structural Steel" (GB/T700-2007).

2. Rust removal method and rust removal grade requirements:

(1). Steel components must be surface treated, and the derusting method and derusting grade shall comply with the relevant provisions of the current national standard "Steel Surface Corrosion Grade and Derusting Grade Before Painting" (GB8923-88).

(2). Derusting method: steel components can be derusted by sand blasting or shot blasting. If chemical derusting is used, a treatment solution with two or more functions of derusting, phosphating and passivation should be selected, and its quality should be It complies with the provisions of the current national standard "General Technical Conditions for Multifunctional Steel Surface Treatment Fluid" (GB/T 12612-2005).

(3). Rust removal level: the rust removal level should meet the requirements of Sa2 1/2.

3, anti-corrosion requirements:

(1). Steel components adopt the anti-corrosion method of metal protective layer. The steel structure supports are all coated with hot-dip galvanized coating. The hot-dip galvanized coating must meet the relevant requirements of "Technical Requirements and Experimental Methods for Hot-dip Galvanized Coatings of Steel Parts with Metal Coverings" (GB/T13912-2002). The thickness is not less than 80?m.

(2). Detection of galvanized thickness: The thickness of galvanized layer shall be tested according to the method provided in "Technical Requirements and Experimental Methods for Hot-Dip Galvanized Coating of Steel Parts with Metal Covering".

(3). Anti-deformation measures of hot-dip galvanizing: adopt a reasonable anti-deformation galvanizing scheme to prevent obvious deformation of components after hot-dip galvanizing.

4. Aluminum alloy material

(1). Material requirements: The material is generally 6061 or 6063.

(2). Requirements for mechanical properties: The quality, chemical composition and mechanical properties of the selected aluminum profiles must comply with the relevant provisions of GB5237.1.

(3). The surface treatment must meet the technical requirements, in line with GB5237.2-2004 "Aluminum Alloy Building Profiles Part 2: Anodizing and Coloring Profiles".

(4). The appearance quality of the profile conforms to the regulations in GB5237.2-2004. The surface of the profile should be clean and smooth, and serious defects such as cracks, peeling, corrosion and air bubbles are not allowed.

When choosing solar photovoltaic brackets, you can see products made of different materials. The brackets made of aluminum alloy and the brackets made of stainless steel have higher practical application value, and brackets of different materials can be used There are also certain differences in time and installation methods, which can meet the application needs of different places and regions